VEKA’s new line of decorative foils

VEKA Fine Structure bears a strong resemblance to powder-coated aluminium windows in terms of both look and feel. The fine surfaces go wonderfully with modern architectural styles such as the popular industrial look in which all kinds of materials and surface structures are mixed and matched for high contrast, such as exposed concrete, steel, bricks and wood.

The surface is especially impactful as incident light is reflected in different directions by the fine structuring. This results in a matt look which, together with the carefully selected colours, effuses elegance while also making a confident mark.

- Striking look

- The latest trend colours

- Perfect highlights for modern architecture

- First-class VEKA quality

- Especially hard-wearing, weather-resistant and scratchproof

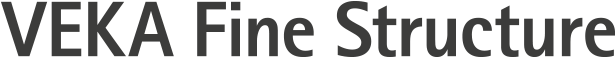

VEKA Fine Structure is currently available in eight popular trend colours:

- anthrazitgrau Feinstruktur

- schwarz Feinstruktur

- schiefergrau Feinstruktur

- quarzgrau Feinstruktur

- basaltgrau Feinstruktur

- silbergrau Feinstruktur

- umbra Feinstruktur

- verkehrsweiß Feinstruktur

Find out more:

![[Translate to English:] VEKAMOVE 76 [Translate to English:] VEKAMOVE 76](/fileadmin/veka/logos/logo_VEKAMOVE76.png)

![[Translate to English:] VEKAFAST [Translate to English:] VEKAFAST](/fileadmin/veka/logos/logo_VEKAFAST.png)

![[Translate to English:] VEKA PURE 82 [Translate to English:] VEKA PURE 82](/fileadmin/veka/logos/logo_VEKAPURE82.png)

![[Translate to English:] VEKA AluConnect [Translate to English:] VEKA AluConnect](/fileadmin/veka/logos/logo_veka-aluconnect.png)

![[Translate to English:] VEKAMOTION 82 [Translate to English:] VEKAMOTION 82](/fileadmin/veka/logos/logo_vekamotion82.png)

![[Translate to English:] DBS [Translate to English:] DBS](/fileadmin/veka/logos/logo_DBS.png)

![[Translate to English:] DBS WinDo Imaging [Translate to English:] DBS WinDo Imaging](/fileadmin/veka/dbs/dbs-windoimaging.png)

![[Translate to English:] DBS WinDo Planning [Translate to English:] DBS WinDo Planning](/fileadmin/veka/dbs/dbs-windoplanning.png)

![[Translate to English:] DBS WinDo Ordering [Translate to English:] DBS WinDo Ordering](/fileadmin/veka/dbs/dbs-windoordering.png)

![[Translate to English:] DBS WinDo Experts [Translate to English:] DBS WinDo Experts](/fileadmin/veka/dbs/dbs-windoexperts.png)

![[Translate to English:] DBS WinDo Flow [Translate to English:] DBS WinDo Flow](/fileadmin/veka/dbs/dbs-windoflow.png)

![[Translate to English:] Texino [Translate to English:] Texino](/fileadmin/veka/logos/Logo_Texino.png)